Chief Investigator: Dr Reza Hassanli

Year commenced: 2020

Problem

Glass fibre reinforced polymer (GFRP) reinforced concrete is a maintenance-free material which can extend the lifetime of structures to 150 years or more (compared to only 30 to 50 years in conventional reinforced concrete). It is a great choice for structures located in aggressive environments such as marine structures, where steel corrosion is a problem, and the possible savings from this can be spent on new infrastructures.

Unfortunately, in Australia, we do not have a design code for GFRP-reinforced concrete yet, and hence engineers are reluctant to use such materials. Through research we are trying to familiarise industry, engineers, construction managers and asset owners with GFRP, and at the same time move towards developing a design code.

Project Summary

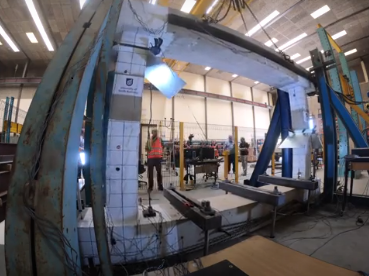

Our project aimed to develop design capacity tables for connections of precast concrete members reinforced with GFRP bars. Different connections in GFRP reinforced concrete made up of precast elements were experimentally tested to find a suitable and cost-effective solution and to accelerate the construction procedure. We manufactured and tested non-element level test specimens under reverse cyclic loading with incrementally increasing displacements.

Impact

A highly workable epoxy resin with high early strength and non-shrinkable properties was used in the pocket areas to connect the precast elements to accelerate the construction procedure. We discovered that the frames displayed a superior ability to withstand large displacement with a stable response.